Multi-Material Spark Plasma Sintering Modeling

Predicting Interface Behavior and Final Geometry in Multi-Material Spark Plasma Sintering: Design Insights from Validated Multiphysics Process Modeling

Project Overview

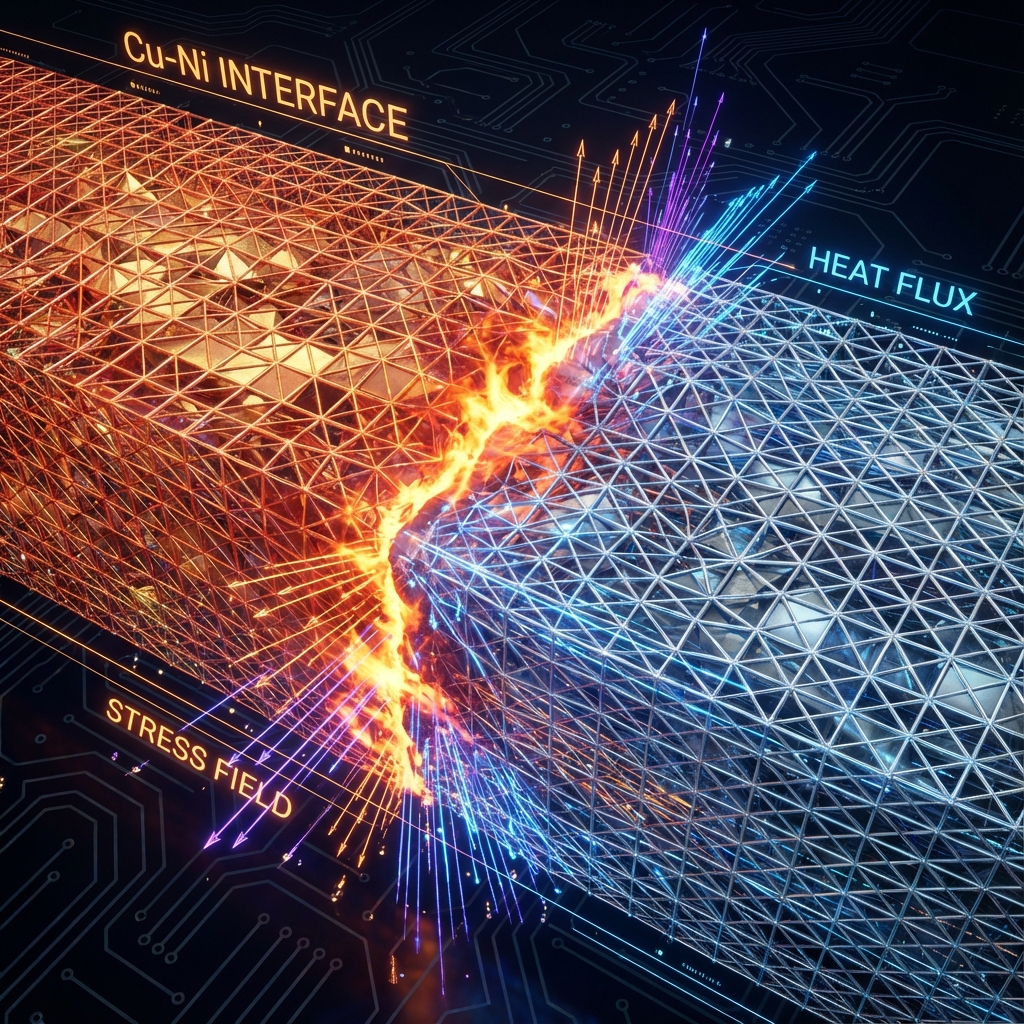

This project introduces a validated electro-thermo-mechanical modeling framework to predict how interfaces behave and geometries evolve during multi-material spark plasma sintering (SPS). Using copper–nickel systems, the study demonstrates how fully coupled finite element simulations can replicate real process behavior and provide actionable design guidance for achieving high-precision multi-material components.

Problem & Motivation

Multi-material SPS enables architected components with tailored properties but suffers from differential densification and misalignment between dissimilar materials. Experimental trial-and-error cannot easily capture how current flow, localized heating, and stress interact at interfaces. A predictive and validated multiphysics model was needed to explain these coupled phenomena and guide powder deposition and interface orientation design.

Research Contributions

- Developed a fully coupled finite element model integrating electrical, thermal, and mechanical interactions for Cu–Ni SPS.

- Demonstrated that porosity-dependent constitutive parameters from single-material SPS can be directly transferred to multi-material systems.

- Achieved less than 1% deviation between simulated and experimental temperature and densification data.

- Revealed that porosity imbalance drives interface displacement, providing a direct design lever for geometric precision.

Technical Highlights

- Tools & Platforms: COMSOL Multiphysics®, experimental SPS setup.

- Methods: Electro-thermal–mechanical finite element analysis.

- Models Used: Sintering material law for copper and nickel powders.

- Performance: Model predicted final geometry and interface displacement with >93% accuracy, confirming parameter transferability.

Results & Impact

The validated model precisely reproduced temperature histories and densification kinetics, confirming strong predictive capability. Simulations revealed that interface geometry dictates current redistribution, localized heating, and final interface displacement. Adjusting porosity and initial interface alignment allows targeted control of post-sintering geometry. This framework provides design-level insights that extend beyond experimental limits, enabling optimization of powder deposition and interface design for advanced multi-material manufacturing.

Publication Details

Journal: Awaiting

Year: 2025

DOI: Awaiting