Multiphysics Simulations of Spark Plasma Sintering Process

Two-Stage Framework for Material Parameter Identification in Spark Plasma Sintering

Project Overview

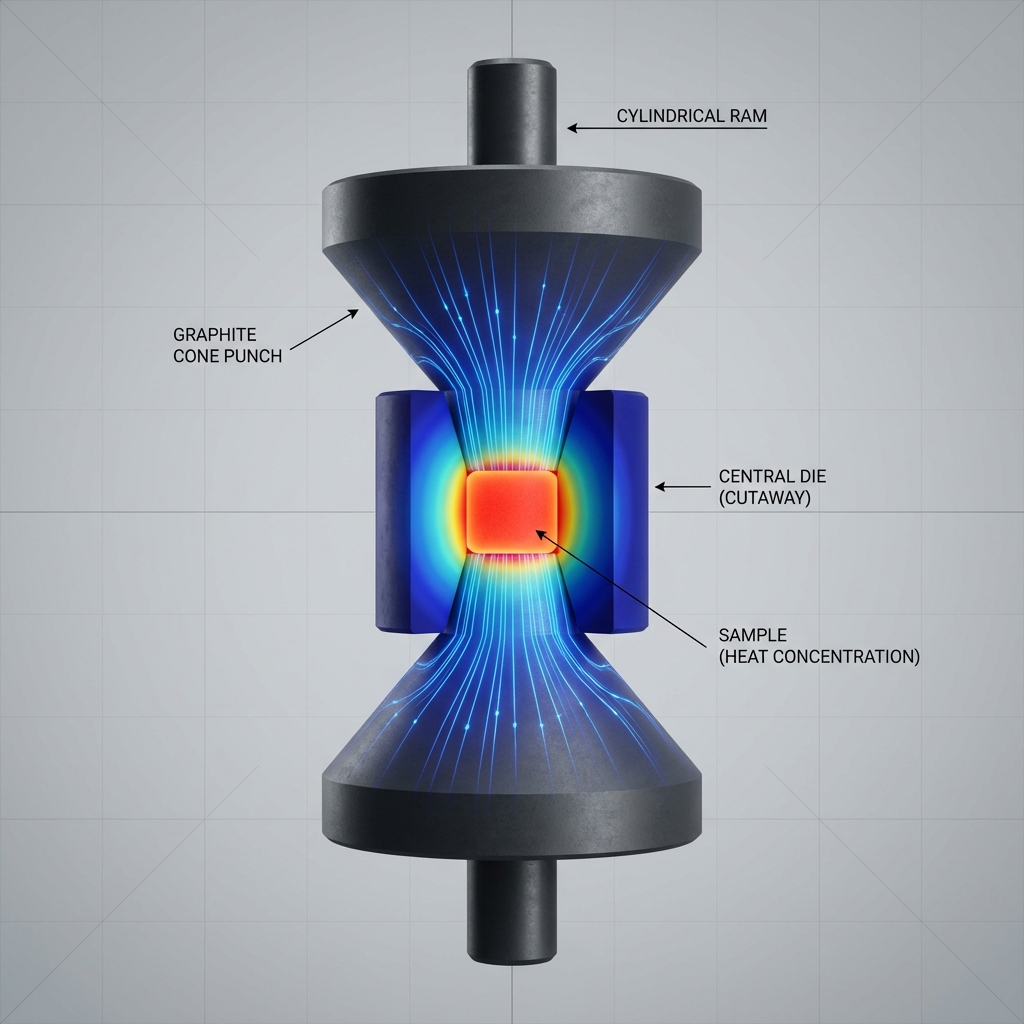

This project addresses a major challenge in spark plasma sintering (SPS): the accurate identification of material parameters needed for finite element simulations. We developed a novel two-stage numerical–experimental framework that uses COMSOL Multiphysics and genetic algorithm optimization to identify thermal, electrical, and mechanical parameters with high precision.

Problem & Motivation

Accurate SPS simulations require precise material data (thermal conductivity, electrical resistivity, creep parameters) which are often temperature-dependent and difficult to measure directly during the process. Traditional calibration methods are often ad-hoc or assume constant values, leading to significant simulation errors.

Research Contributions

- Developed a two-stage identification strategy separating electro-thermal calibration from mechanical calibration.

- Used genetic algorithms (GA) coupled with FEM to minimize error between simulation and experimental data.

- Validated the identified parameters for both Graphite (mold material) and Copper/Nickel powders.

- Achieved a relative density prediction error of less than 2.3% for unseen heating rates.

- Provided a transferable methodology applicable to any conductive powder system in SPS.

Technical Highlights

- Tools & Platforms: COMSOL Multiphysics, MATLAB (for Optimization), Genetic Algorithms.

- Methods: Inverse parameter identification, Finite Element Analysis (FEA), Creep modeling (Norton law, Shima-Oyane).

- Validation: Compared simulated temperature and displacement curves with experimental pyrometer and LVDT data.

Results & Impact

The framework enables highly accurate predictive modeling of the SPS process, reducing the need for expensive experimental trial-and-error. By accurately capturing the temperature-dependent evolution of material properties, the model can predict final density and shape with high fidelity, facilitating the optimization of sintering cycles for new materials.

Publication Details

Journal: Mechanics of Materials

Year: 2023

DOI: 10.1016/j.mechmat.2023.104834